Electrifying Process Heat at Preens

Whirika’s Erin Roughton and Rick Wellington of Preens, in front of the E-Boiler.

Preens Apparelmaster and Linenmaster is a century-old commercial laundry operation based in Dunedin, New Zealand, serving Dunedin, Gore, and Oamaru. Until recently, Preens relied primarily on fossil-fuel boilers (diesel) for process heat - a significant source of carbon emissions and energy costs. To align with its sustainability goals and reduce its carbon footprint, Preens sought to transition to low-emission energy systems that could support reliable and efficient thermal processes in commercial laundry operations.

We supported Preens through the feasibility and scoping phase of the project, identifying and evaluating clean energy solutions that could decarbonise process heat and save energy at Preens’ Dunedin operations. This included:

Assessing options for replacing fossil-fuelled boilers with electric alternatives

Designing a system that could integrate advanced heat recovery and renewable energy sources

Supporting Preens through planning and funding pathways

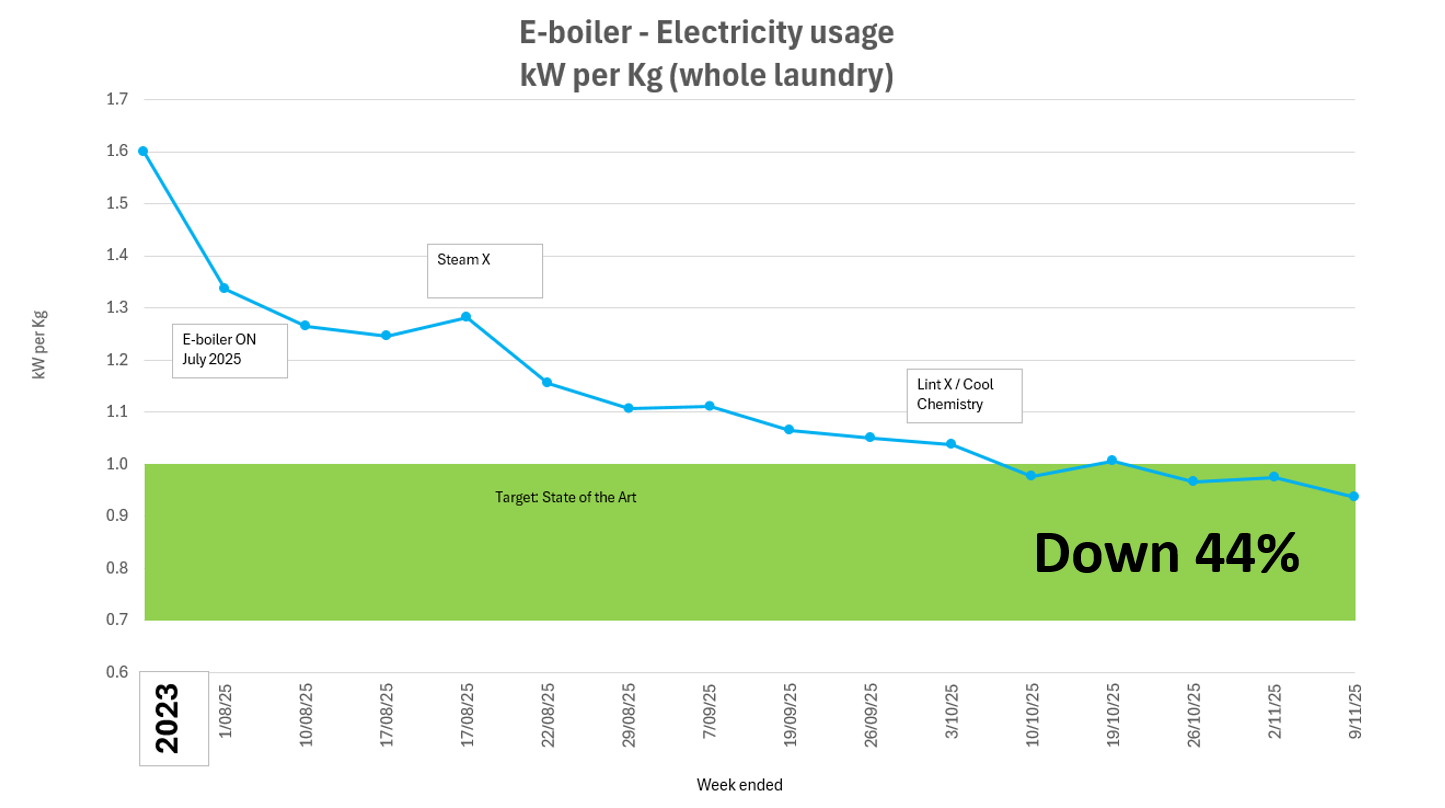

With co-funding from EECA (Energy Efficiency and Conservation Authority) and delivery support from Dunedin-based project managers Feldspar, we were able to collectively deliver the installation of a 2 MW electric boiler and include advanced European heat recovery technology called Steam X – which puts low grade steam 4 bar back into heating the water.

A First for Australasia’s Commercial Laundry Sector

The 2 MW electric boiler, equipped with European advanced heat recovery technology and manufactured locally by Energy Plant Solutions, was the first of its kind in Australasia. The system was fully commissioned in July 2025 and now delivers the majority of process steam required for laundry operations.

Key technical features:

Consistent steam at 10.5 bar (186 °C) pressure.

Integrated heat recovery to improve overall energy efficiency.

Designed for renewable electricity and future scalability (e.g., solar integration).

Outcomes & Impact

Emissions reduction: Estimated >800 tonnes CO₂-equivalent avoided annually, equivalent to removing ~320 utes from NZ roads each year.

Energy efficiency: Energy consumption per kilo of laundry processed reduced by 44 %.

Renewable integration: Boiler runs entirely on certified renewable electricity, positioning Preens among the lowest-emission commercial laundries globally.

Water savings: Heat recovery and reuse systems also halved water consumption across the facility.

Though a diesel boiler remains on standby for specific operational needs (e.g., maintenance and winter grid constraints), the electric system now supplies the vast majority of process heat.

Looking Ahead

Preens plans additional sustainability enhancements such as solar PV installations, and continues to explore ways to further improve resource efficiency - exemplifying a continuous improvement mindset.

Looking to do something similar at your operations? Get in touch with our Principal Energy and Carbon Specialist, Erin Roughton.